The Sobye Belt Filter

The high efficiency filter replaces standard primary filtration of municipal wastewater and sedimentation processes and delivers the benefits of a smaller footprint and a significantly reduced investment while removing BOD and suspended solids at least equivalently to conventional settlement. The system produces an extremely dry sludge and chemicals are normally not required which facilitates the further treatment or processing of recoverable material.

How it works

The screened wastewater is fed into the filter where the particles are separated as the water passes through the filter fabric. The screen fabric rotates when it needs cleaning and is cleaned principally by brush and then by washwater.

The particles separated by the brush are transported internally in the filter to a press that de-waters the sludge to very low moisture content. The wastewater is drained out of the filter separately and can normally be fed back to the incoming water.

Compact and efficient

The Sobye filter has an exceptionally high filtering capacity in relation to its small size. It is therefore an excellent choice when space is limited and it provides savings because no large structures or tanks need to be built. The filter fits well into an existing facility and is also suitable as a channel filter. The filter tank casing is made of stainless steel (EN1.4404) and wetted parts are IP-67 rated.

Low operating costs

The Sobye filter uses an integrated brush for cleaning the filter fabric, which means no compressor, or pump is required. Competitor belt filters using compressed air for cleaning require energy-consuming compressors that are expensive both to purchase and operate.

Applications

More than 200 systems are currently in use, with around 100 of these in the municipal primary treatment market where they are used for pre-filtering of municipal wastewater. Other applications include fish farming and fish processing.

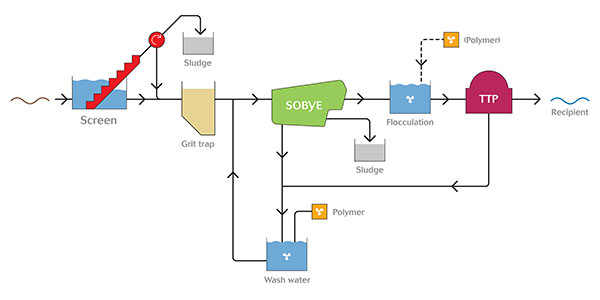

Flow Example, Municipal Waste Water

Flexible and robust construction

The filter is available in three standard versions with different capacities. Custom models have also been developed to meet other specific industry requirements. The belt filter can also form part of a larger system. The filter comes with a very strong and robust fabric that can withstand the wear and pressure drop of primary treatment demands.

User-friendly working environment

Cleaning the fabric with a brush and washwater prevents the release of particles and bacteria into the air. Together with a low noise level this gives operators a good working environment. Operating costs also show that brush and washwater is a highly competitive method of belt cleaning. The required ventilation from the screens is only 5-15 cbm/h, which means very low ventilation costs.

Smart design – easy to maintain

The Sobye filter fabric is incorporated into a cassette that can be easily removed from the filter tank for maintenance and repair. The fabric is made of polyester, which ensures an exceptionally long operating life cycle. Because the fabric can easily be replaced in about 30 minutes, without the need to change the belt filter in general, future changes in filtration requirements can be readily accommodated.

Putting you in control

The belt filter can be delivered together with a control panel and can be equipped with control instrumentation and monitoring to meet specific needs such as remote control.

| Downloads | |

View Case Studies View Case Studies |