Filter Distributors

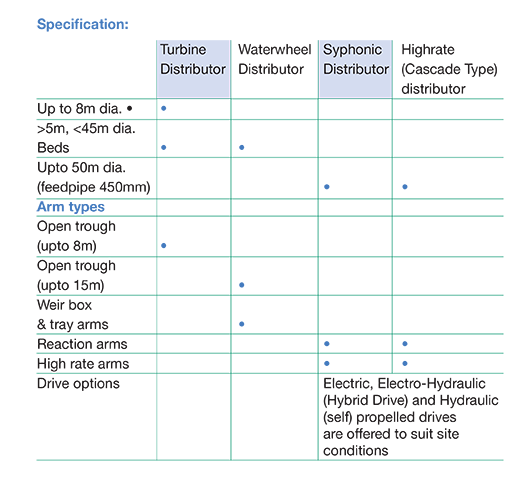

Jacopa’s rotary distributors are designed to evenly distribute sewage over a trickling filter. Rotary distributor mechanisms are widely accepted as the most flexible and resilient method of biologically treating wastewater. A range of drive mechanisms are offered to suite intermittent, low or continuous high flow conditions up to 50m bed diameters.

| Downloads | |

View Case Studies: Filter Distributors View Case Studies: Filter Distributors |