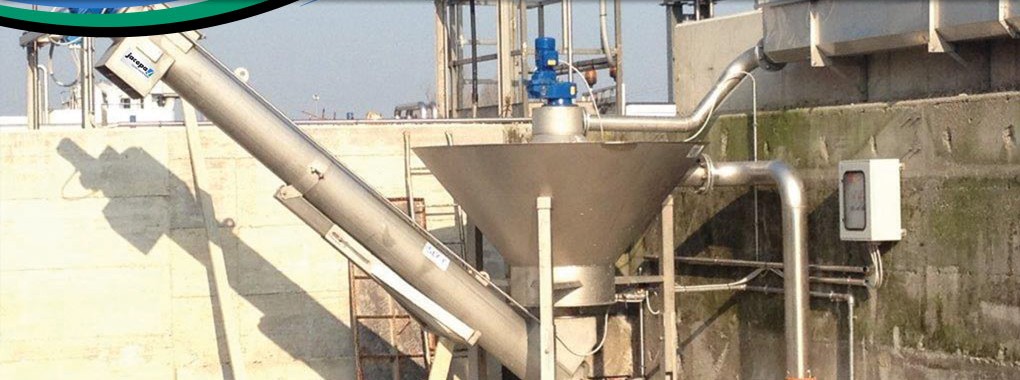

Jacopa® Sand/Grit Separator

The grit classifiers separate and wash sand from wastewater (municipal or industrial). It consists of a large conical hopper for sand/grit settling, sedimentation and washing. A tubular screw is used to convey and dewater the collected material, the conical shape of the hopper plus the counter washing system and the low rotational stirrer allow the washing of sand/grit and the separation of organic matter.

Available in 3 standard sizes.

| Specification: | |

| Models | 30, 60, 90 |

| Pumped Capacity (l/s) | up to 25 |

| Power (kw) | 0.75 or 1.1 |

| Removal efficiency | 90% up to 200 um |

| Treated capacity | Up to 90% Dewatering >5% Organic Content Up to 1.5m3/hr |

| Material | 304L or 316L Stainless Steel |