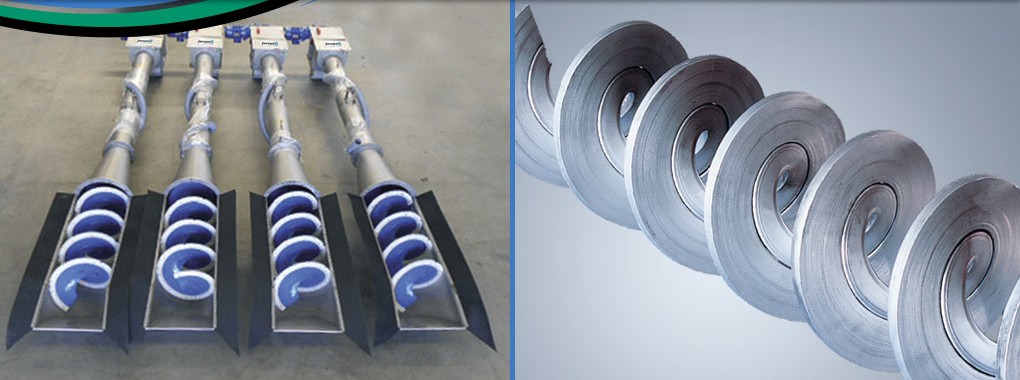

Jacopa® Spiral Screen

The Jacopa® spiral screening equipment is used for the removal of fine solids. The screen utilises a shaftless spiral which elevates the collected screenings up & out of the effluent flow. This screen is generally used for treating flows of up to 300 l/s with a 6mm 2D filter basket.

| Specification: | |

| Maximum capacity | Up to 300l/s |

| Screen aperture (mm) | 3 to 10 mm in 2 direction |

| Screen mounting angle | 35° to 45° |

| Washwater supply | 5 bar, |

| Options | Integral Compaction/Tank Mounted/Wedge Wire (0.25 to 3.0mm) |

| Material Body | 304L or 316L Stainless Steel. |

| Downloads | |

View Case Studies View Case Studies |