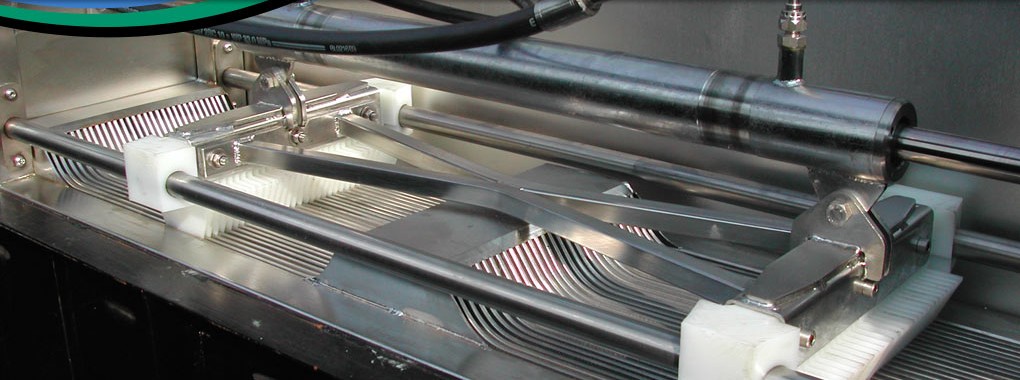

Copa Raked Bar Screen

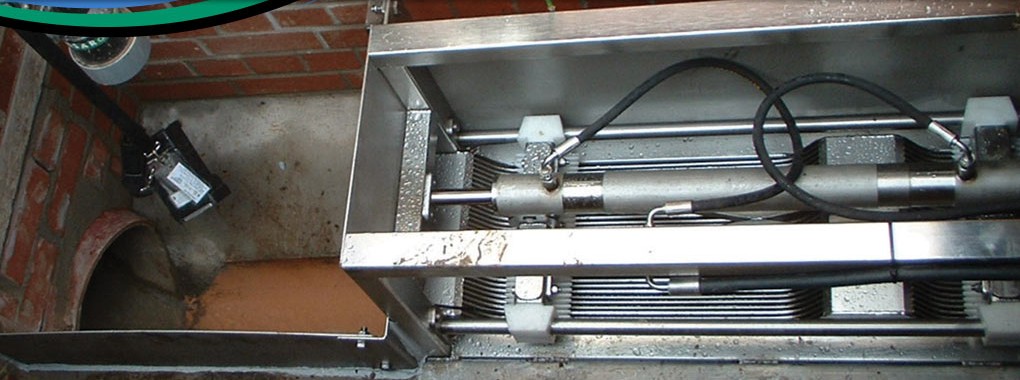

The Copa raked bar screen is ideally suited to both new and existing Combined Sewer Overflow (CSO) chambers where high frequency spills can be expected. Its modular design is ideal for retro-fit installations (requiring little or no civil work to the existing CSO chamber) and allows the unit to be assembled below ground through just a 600mm diameter manhole.

Flow rates from 50 – 3000 litres / second can be catered for by a single screen, although multiple units may be used to increase flow capacity

4/6/10mm bar screening suitable for high volume and frequent spill CSO’s