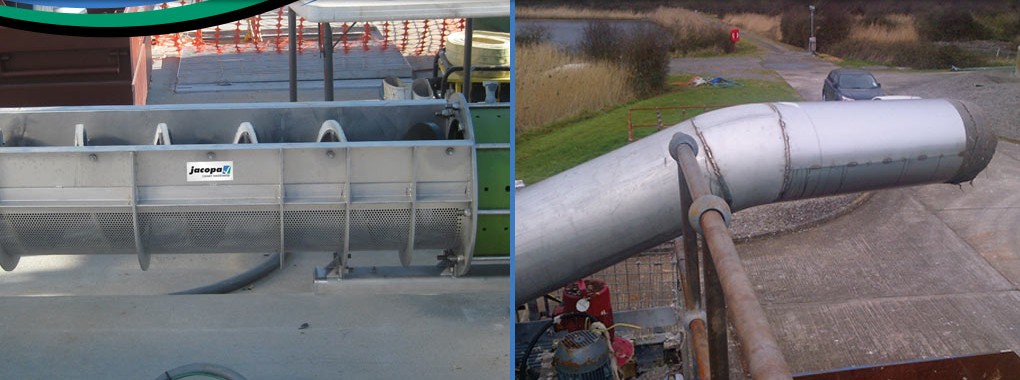

Jacopa® Screw Compactor

The Jacopa® screw compactor incorporates the original Jones+Attwood technology that has a proven record of reliability and robustness. This design incorporates a 9mm thick drainage trough for ruggedness and 6mm tapered holes for improved drainage– built with lowering life cycle costs in mind.

Available in 5 standard sizes.

| Specification: | |

| Models | 150, 200, 300, 400, 500 |

| Screening Loading | 0.5, 1.25, 3.0, 6.0, 9.5 |

| Launder flow upto (l/s) | 1.5, 3.0, 5.0, 6.5, 8.0 |

| Material | Mild Steel Standard |